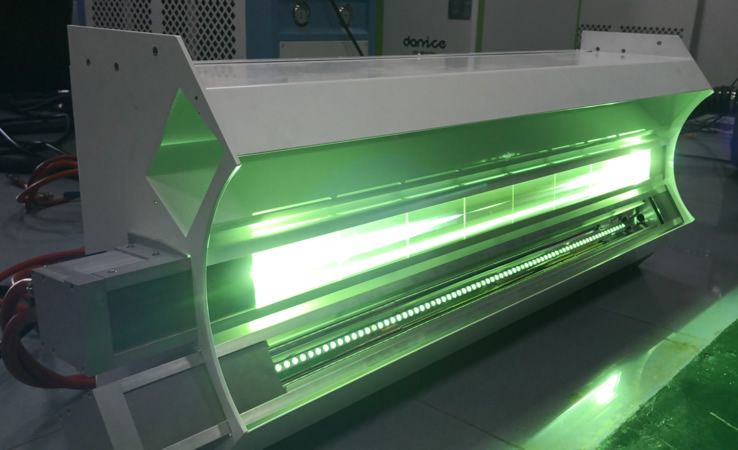

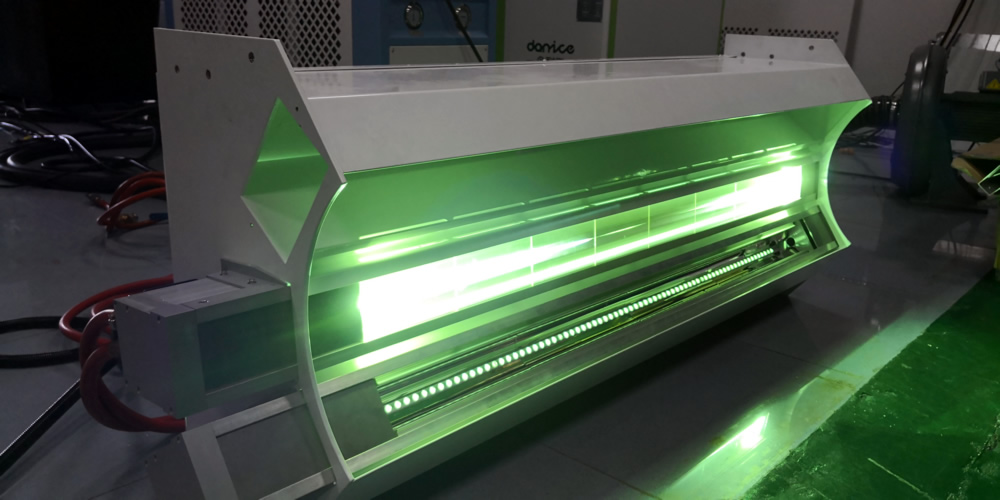

Uniform and stable light emission, strong light, shorten product curing time and improve production efficiency.

It is especially suitable for liquid crystal edge sealing, plastic substrates, film printing, and medical devices that require a small heating area.

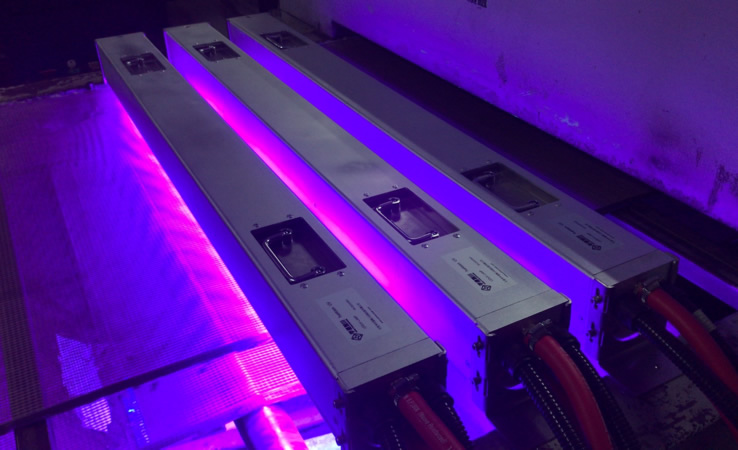

The power consumption is 10% of the traditional mercury lamp curing machine, which can save 90% of the electricity.

The service life can reach 30,000 hours, reducing the cost of consumables.

High Security

The whole machine has more than 130 safety fault detection and automatic protection, which can effectively protect the safety of people and machines.Energy Saving

Transformer power reaches 0.85 or more, high efficiency and energy saving, saving printing cost.Man-machine Dialogue

Fully automatic computer friendly man-machine dialogue interface, Chinese and English display options are available.Stable Performance

Adopt original products from Germany, Japan, Taiwan and other brands to ensure stable system performance.

Core Element

High density LEDCOB packaging technology 15-18W/cm²Drive Control

Stepless dimming, real-time monitoring of temperature, time, system failure alarmRadiated Power

R700、CD102、XL105 、KBK 105 (Length 1050mm Power 5-10KW)Ink Suitability

The use of hybrid UV curing system can be compatible with various traditional UV inks in the market

Energy Efficient

Concentrated energy and high power Suitable for curing deep products, focusing UV lampshade is small in size and easy to maintain.Cooling Method

Using water cooling and auxiliary air cooling, the overall structure is simple, and the fully closed circulating water circuit can effectively reduce water leakage failures.Shutter Drive

The linear cylinder gear structure is adopted to open and close the shutter smoothly, and the failure is reduced.Cryogenic Design

The workshop temperature is within 25°C, and the temperature of the printed product can reach no higher than 42°C after drying.

More than ten years of industry experience, hundreds of successful UV equipment installation cases.

Products are widely used in offset printing, gravure printing, iron printing, coating, flexo printing, labels and various industrial curing applications.

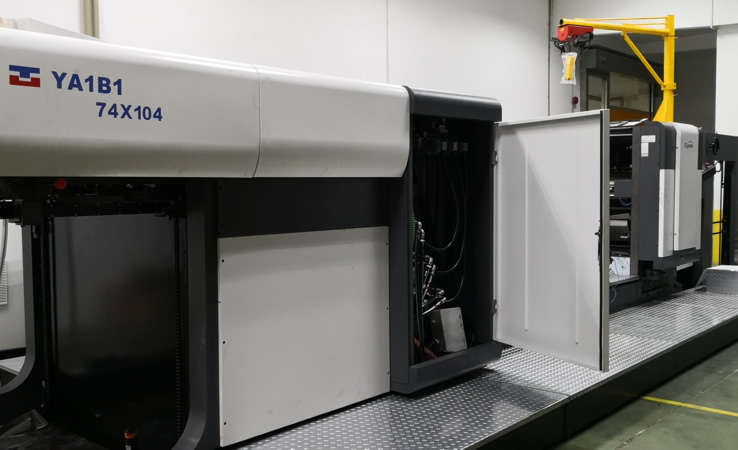

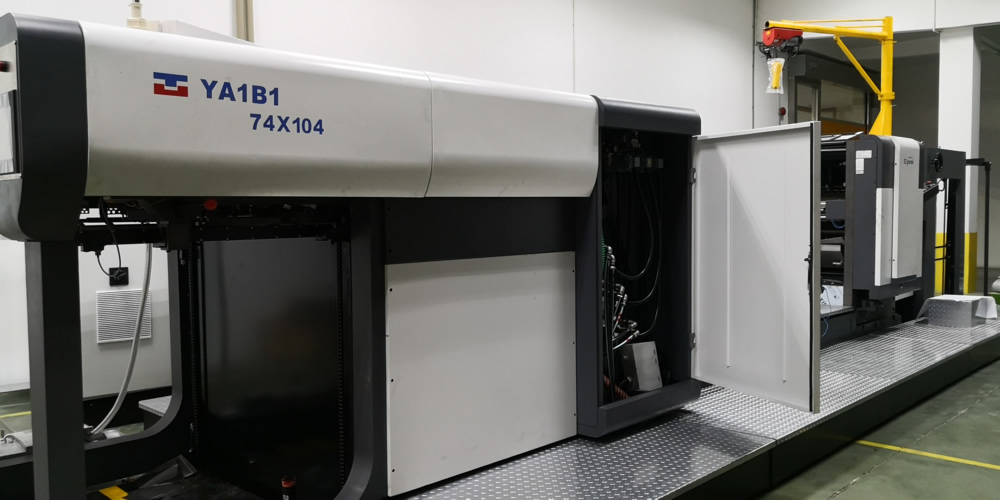

Regardless of the brand, type, model and year of your printing press, Hengtong can customize a suitable UV system for your printing press.

Engaged in the application and development of UV printing equipment for a long time

Hengtong brand huntoon UV drying system was established

LEDUV, UV, IR/IR drying unit

Have senior and high-quality engineers in the printing industry.

Long-term service for large-scale printing enterprises at home and abroad.

Continuously introduce new foreign technologies and accessories, and continue to develop and innovate on the basis of our own accumulation.

Professional technicians come to install and train employees to use UV equipment.

The equipment is guaranteed for 1 year; the after-sales response is quick and a special person will visit regularly.

Quickly formulate solutions and guide customer operations or on-site response to assist customers in solving problems.

It is mainly to increase the brightness and artistic effect of the product, protect the surface of the product, its high hardness, corrosion resistance, and scratches are not easy to appear. Can only be solved by spot UV or sanding.

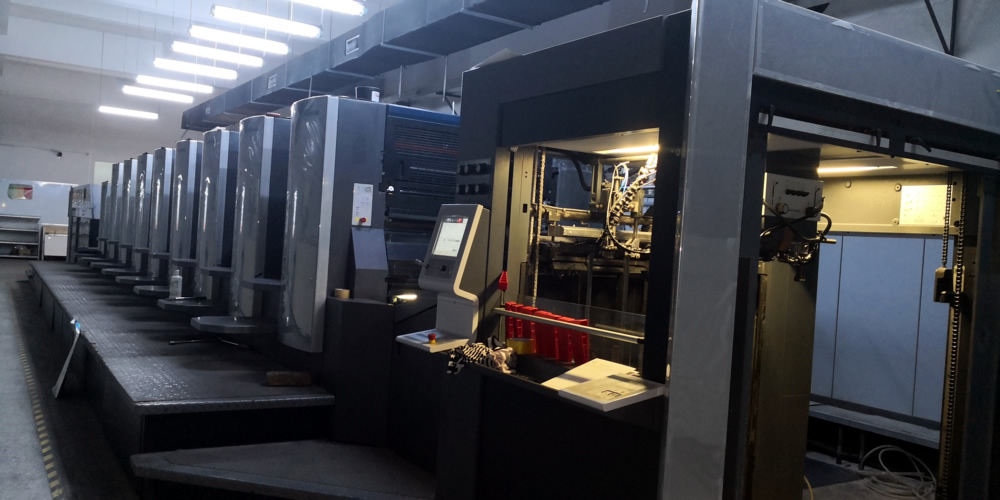

Heidelberg Heidelberg UV drying equipment-Gua

Heidelberg Heidelberg UV drying equipment-Gua Heidelberg Heidelberg UV drying equipment -10

Heidelberg Heidelberg UV drying equipment -10 Manroland UV Drying Equipment - Tiger Color P

Manroland UV Drying Equipment - Tiger Color P

For gravure high-speed printing equipment, it can solve the problem of high temperature, strong ozone smell and short service life of UV lamps.

Single-sheet concave UV drying system ZHLUV

Single-sheet concave UV drying system ZHLUV Single sheet concave UV drying system to far

Single sheet concave UV drying system to far

Suitable for offset, flexo, coating and gravure printing presses. Simple structure, beautiful, lightweight and easy to maintain! patented technology!

Capture Rotogravure UV

Capture Rotogravure UV

Suitable for TFT-LCD optical film (BEF brightening film, Diffuser diffusion film...) UV coating, suitable for IMD/IMF/IML UV coating coating, you can choose the front or back or both sides of the in-line protective film.

Coating Machine UV Case

Coating Machine UV Case

Widely used in tobacco and alcohol anti-counterfeiting, certificate labels, electronic appliances, metal, plastic products, injection molding products, glass, ceramics, building materials, paper, cloth, leather and other material surfaces

Suitable for TFT-LCD optical film (BEF brightening film, Diffuser diffusion film...) UV coating, suitable for IMD/IMF/IML UV coating coating, you can choose the front or back or both sides of the in-line protective film.

Hengtong Zhichuan is a technology-based enterprise integrating R&D, production, sales and service of ultraviolet and infrared (UV, IR) drying equipment. With senior and high-quality engineers in the printing industry, they have been serving large-scale

printing enterprises at home and abroad for a long time.

He has been engaged in the application and development of UV printing equipment for a long time,

Focus Us